Introduction

In the ever-evolving world of manufacturing, unexpected challenges can arise at any moment. One such curveball is the sudden absence of a plant manager, thrusting the operation into crisis mode. We'll explore practical steps and strategic maneuvers we had implemented to one of our clients, an industry 4.0 molding manufacturer that

lead to a 15% increase in output despite losing their plant manager.

The Initial Shock

Assessing the Situation:

The first step is acknowledging the reality of the situation. Assess the impact, identify critical areas, and understand the immediate challenges your manufacturing plant faces.

FREE GUIDE:

HOW TO IMPLEMENT LEAN MANUFACTURING STARTER HANDBOOK

Step 1: Stabilize Operations

Temporary Leadership:

Designating a temporary leader is crucial for maintaining continuity in production. This interim leader can either be a seasoned team member or an external consultant with expertise in lean manufacturing. In this specific case, Twenty Helping Hands assumed the role of an interim leader for a 4-month duration. During this period, we organized group leaders, established processes, and instilled structure to enhance the overall flow within the molding manufacturing team.

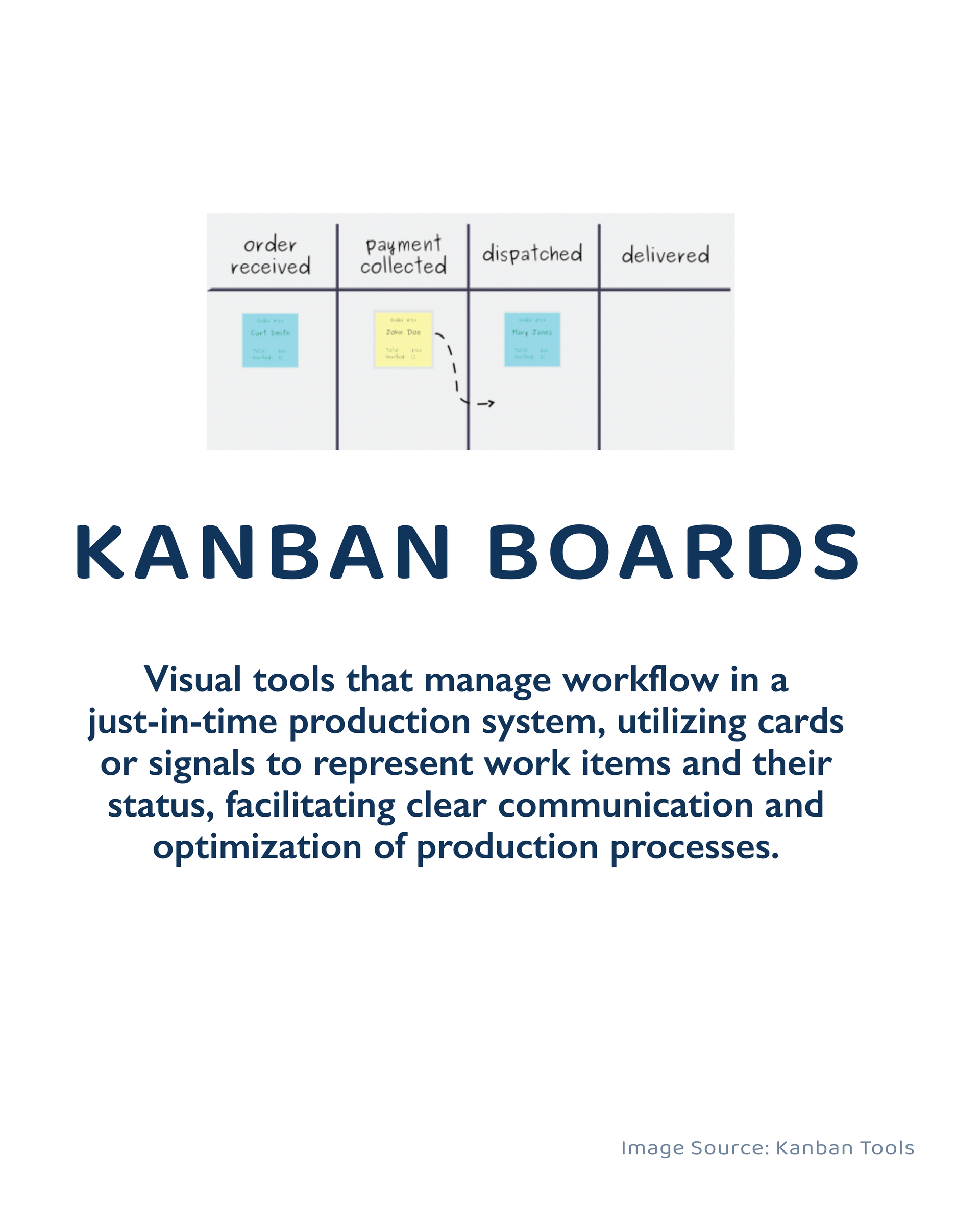

Visualize Operations:

Leveraging visual cues is a powerful shortcut to establishing efficient manufacturing flow. Studies show that

visual communication is processed 60,000 times faster than verbal or written communication making it an undeniable asset in mainstreaming new processes.

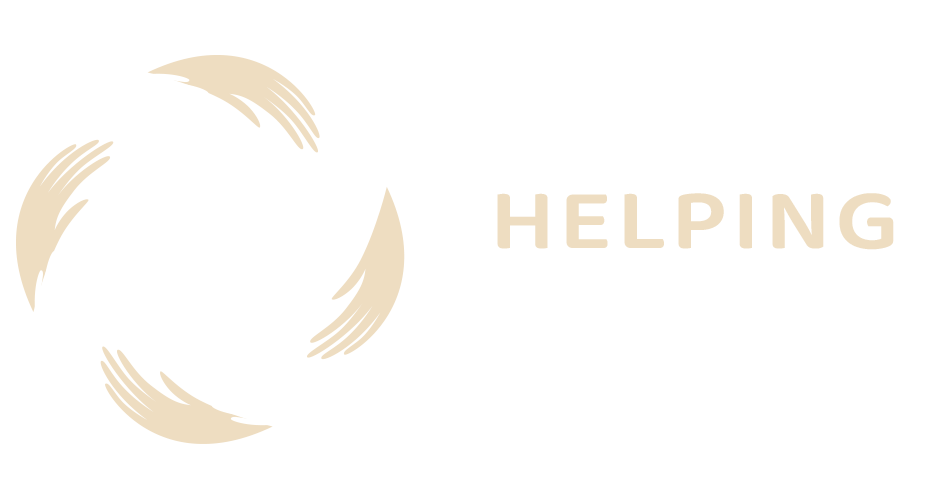

To enhance our operations, we introduced Takt boards to track and visualize production, fostering clarity and empowering the team to collaboratively work towards a shared goal.

What is a Takt Board?

A Takt Board is a real-time visual management tool that tracks production output, aligning with Takt time to meet customer demand. It provides a clear visual representation of production status, aiding in quick identification and resolution of deviations or inefficiencies. Other visual management tools can streamline manufacturing operations.

Since implementing this strategy, the company leveraged a 15% increase in output over its first 10 weeks on the first shift, making room to even implement a second shift that furthers the output.

Step 2: Empower Your Team

Encourage Problem Solving: Fostering a culture of problem-solving and cultivating self-driven leaders is achieved through empowering and nurturing your team members. Utilizing phrases like "What do you think we should do?" encourages initiative and promotes a mindset of solution-oriented thinking.

In our initial discussions with the assembly line supervisor, we actively sought his insights to improve production, a task often overlooked by higher ups, particularly in the absence of a plant manager. Frustration had been mounting on the assembly line due to prolonged robot installation, causing significant delays.

During our conversation, we underscored the imperative of achieving a daily production target of 1,000 units, regardless of the presence of robots. This emphasis sparked inspiration in the supervisor, leading to the implementation of his idea. Consequently, he established a temporary production line perpendicular to the robot line, resulting in the impressive production of 5,000 units the following week—accomplished without resorting to overtime.

This highlights the transformative impact of empowering manufacturing employees with a self-starter attitude through effective delegation.

Step 3: Strategic Hiring

Leverage the crisis to pinpoint skill gaps within your team, paving the way for a more resilient future workforce.

We invested time in repairing the financial books over a 2-month period. Additionally, we crafted a comprehensive job description, outlined core values, and established non-negotiables for the prospective candidate.

As a result, we successfully recruited a seasoned controller with operational expertise. This strategic hiring move played a pivotal role in optimizing ERP systems and financial processes, allowing for a seamless transition out of the interim role at the 4-month mark.

Conclusion

Facing a crisis when your plant manager drops can be daunting, but with a strategic approach and a resilient team, you can not only stabilize operations but also pave the way for continuous improvement. Remember, crisis moments are also opportunities for growth and positive transformation.

FREE GUIDE:

HOW TO IMPLEMENT LEAN MANUFACTURING STARTER HANDBOOK