How to Learn Lean Manufacturing: To Boost Production & Revenue

Introduction

One way to gain a significant edge in the manufacturing industry is by mastering the art of lean manufacturing. But where do you begin, and how can you grasp the fundamental concepts and tools that make lean manufacturing so effective? We'll show you how to learn lean manufacturing and equip you with the knowledge and skills to drive efficiency and success in your organization.

Includes the first 3 steps to starting the Lean Journey for your facility!

Understanding Lean Manufacturing Concepts

At its heart, lean manufacturing is about eliminating waste and maximizing value. Imagine your home: when you declutter and organize, you're following a similar principle by keeping what adds value and discarding what doesn't. The lean mindset focuses on delivering value to customers while minimizing waste – a concept that resonates with our everyday lives.

Key Lean Manufacturing Tools

Lean manufacturing provides a toolbox filled with practical tools & techniques to streamline processes. Some of these tools include:

- 5S: a method that parallels tidying up your workspace for optimal functionality, much like organizing a room.

- Kanban:

operates like a to-do list, ensuring that work is only initiated when there's demand, just like your grocery list for shopping.

- Visual Management: visual tools like charts & graphs to make information accessible, promoting better decision-making & problem-solving.

- One Piece Flow: a technique that involves producing one item at a time, reducing lead times, inventory & overproduction.New Paragraph

Where is Lean Manufacturing Used?

One of the fascinating aspects of lean manufacturing is its versatility. It's not confined to a single industry or sector; instead, it's a universally applicable set of principles. You'll find lean manufacturing in the automotive sector, ensuring the efficient assembly of vehicles, but you'll also see it in healthcare, enhancing the flow of patient care. The adaptability of lean principles is akin to how we apply problem-solving skills to various life situations.

Best Lean Manufacturing Courses

To effectively master lean manufacturing, consider engaging in online learning or practical simulations to apply its tools in a hands-on manner.

Lean Games provides practical business simulation samples to easily understand how to implement lean.

Alternatively, we provide self-paced learning tools and resources that not only aid in comprehending lean manufacturing tools but also empower your manufacturing business to boost production and revenue without the need for additional hires, new equipment, or staff reductions.

SOME OF THESE TOOLS INCLUDE: (clickable)

CLICK TO EXPAND

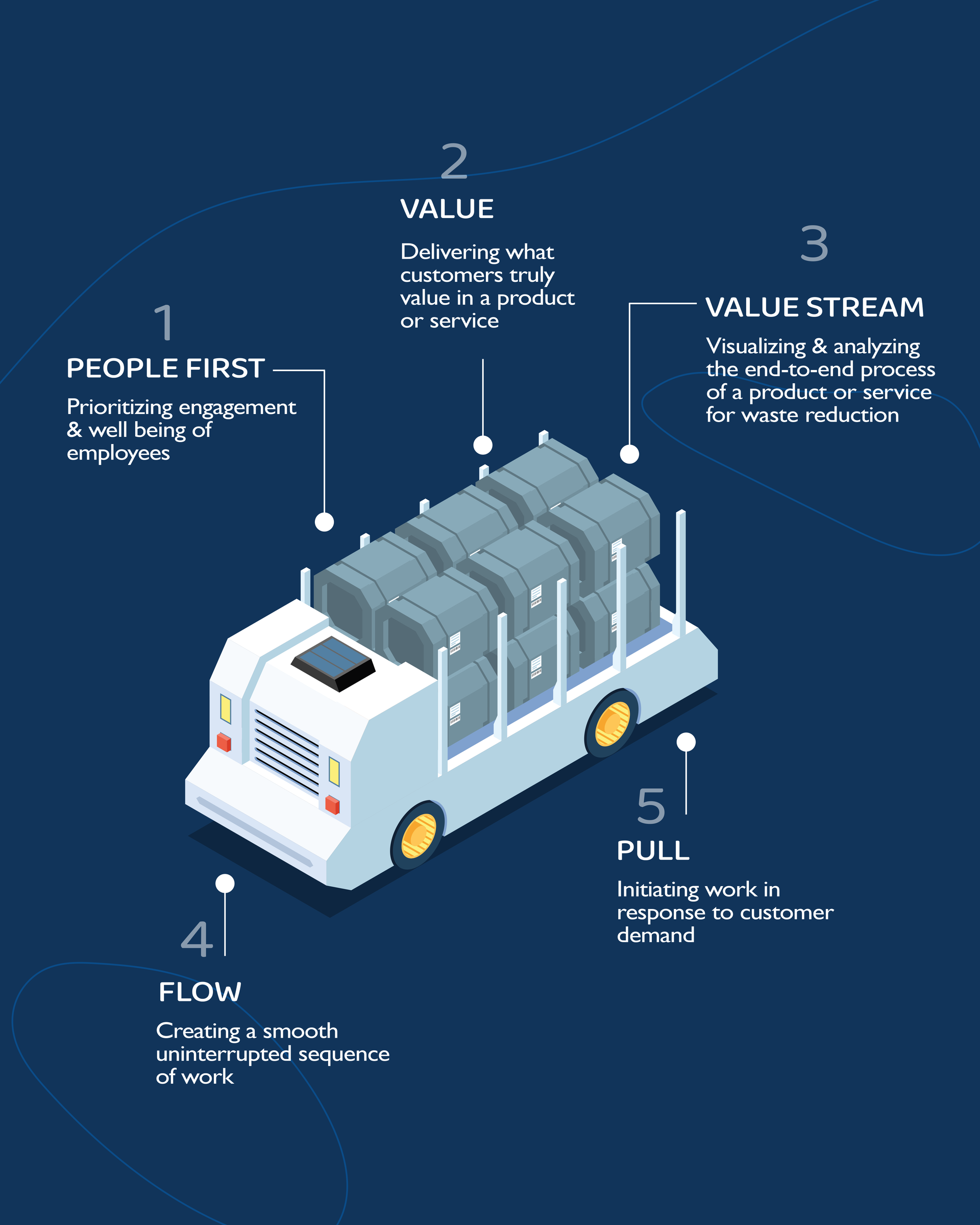

The 5 Principles of Lean Manufacturing

To truly master lean manufacturing, you need to understand its five fundamental principles:

- People First

- Value

- Value Stream

- Flow

- Pull

Think of these principles like planning a smooth, hassle-free commute. Prioritizing the well-being of your employees motivates them to care for your business, making a people-centric approach the most effective tool for achieving this. "Value" defines your destination, "Value Stream" maps out your route, "Flow" ensures a traffic-free journey, "Pull" keeps you moving only when necessary, and "Perfection" signifies an optimized, worry-free trip.

Improving Quality with Lean Manufacturing

Lean manufacturing isn't just about saving money; it's also about delivering a better product. Imagine you're a restaurant aiming for Michelin-star quality. Lean principles would ensure that every dish is prepared with precision and consistency. Fewer errors, happier customers, and a reputation for excellence.

Benefits of Implementing Lean Manufacturing

So, why should your company go lean? Well, apart from the obvious cost savings, lean manufacturing means you can respond quickly to customer needs. This approach has proven increased production & revenue capacity without the need to hire or invest in more machinery. It's like being a chef who can whip up a delicious dish on the spot with the ingredients at hand. Your agility in the market is a game-changer.

How to Learn Lean Manufacturing

Learning lean manufacturing is like learning a new recipe. You can start with books, online courses, or attending seminars. But the secret ingredient is getting guidance from experts. At Twenty Helping Hands, our Lean Manufacturing Consultant, helps you skyrocket revenue without new hires or equipment & accelerate production.

You can book a complimentary call

to see how you can implement lean practices to your company today.

Understanding Lean Production

Lean manufacturing and lean production are two peas in a pod. Lean production is where the rubber meets the road; it's the practical application of lean principles in your manufacturing processes. Picture lean manufacturing as the theory, and lean production as the hands-on practice.

Lean manufacturing isn't just a trend; it's a proven approach to optimizing your processes, reducing waste, and improving quality. So, whether you're in Chicago or anywhere else in the world, the principles of lean manufacturing can help you declutter your business and create a recipe for success.

Hello, I'm Matthew - Chicago Lean Manufacturing Expert

Finding a Lean Manufacturing Consultant in Chicago

If you're in the Windy City, finding a local expert is as easy as ordering deep-dish pizza. Working with a Lean Manufacturing Consultant in Chicago means you have someone who understands your local business landscape, just like a tour guide showing you the best spots in the city.

BOOK COMPLIMENTARY AUDIT